Positive pressure dense phase intermittent pneumatic conveying system

Release date:2023-06-29 Views:1242

In terms of positive pressure dense phase intermittent pneumatic conveying, the company has always been committed to the theoretical research of pneumatic conveying system and the summary of engineering practical experience, focusing on breaking through the key technologies of long distance, large output, low energy consumption and low wear in the process of pneumatic conveying. The core products are PCD type positive pressure dense phase pneumatic conveying bin pump. At the same time to provide systematic, standardized, refined engineering design and technical services. According to the needs of different customers, we make the best design scheme according to the parameters of material nature, conveying distance, conveying capacity, receiving bin capacity, dust removal capacity and geographical conditions. Each equipment has passed the qualified inspection, and each pneumatic conveying system has its own design characteristics, so that customers can truly experience the intelligent management and economic benefits brought by advanced technology products.

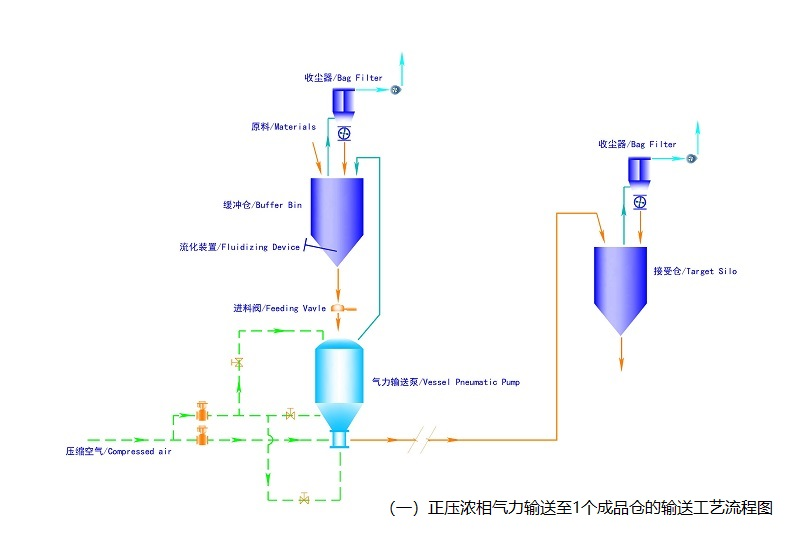

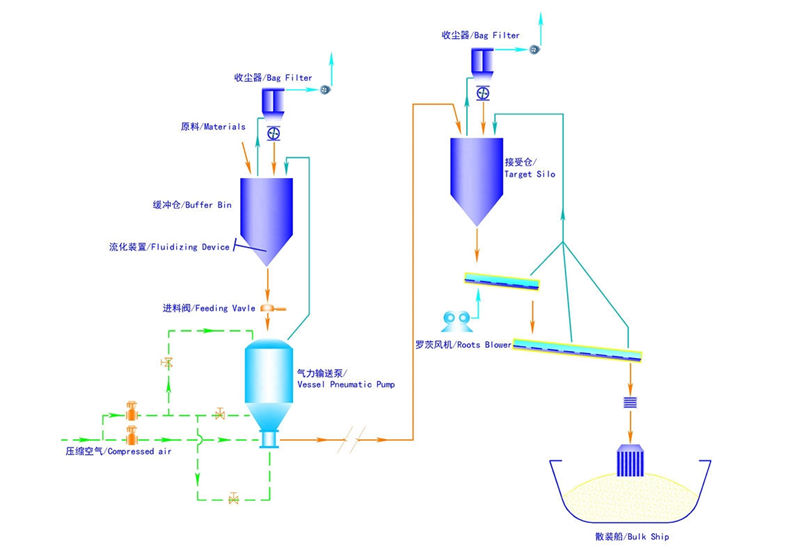

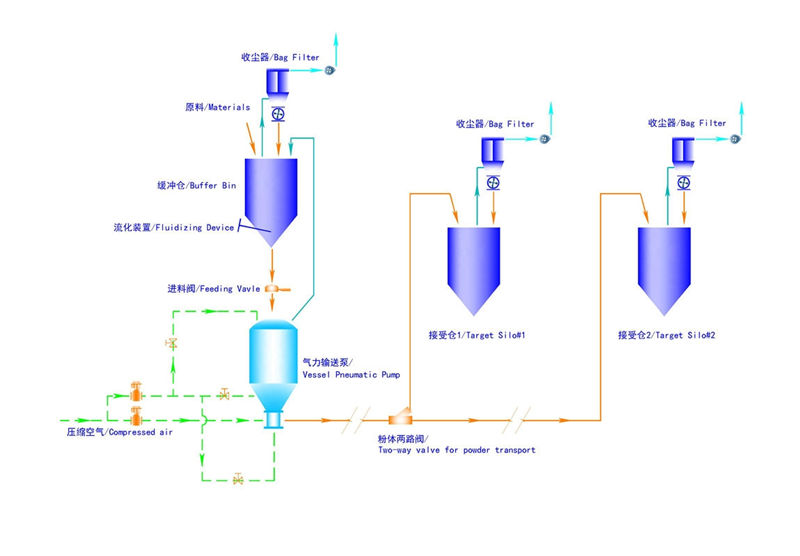

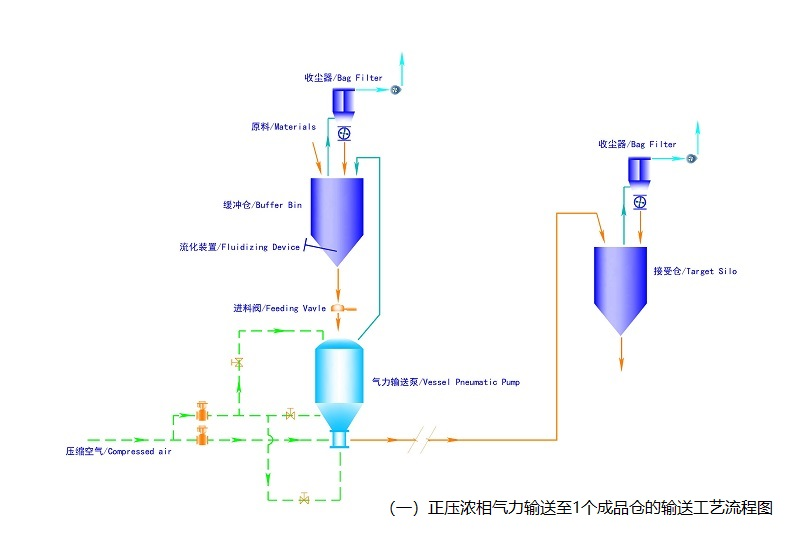

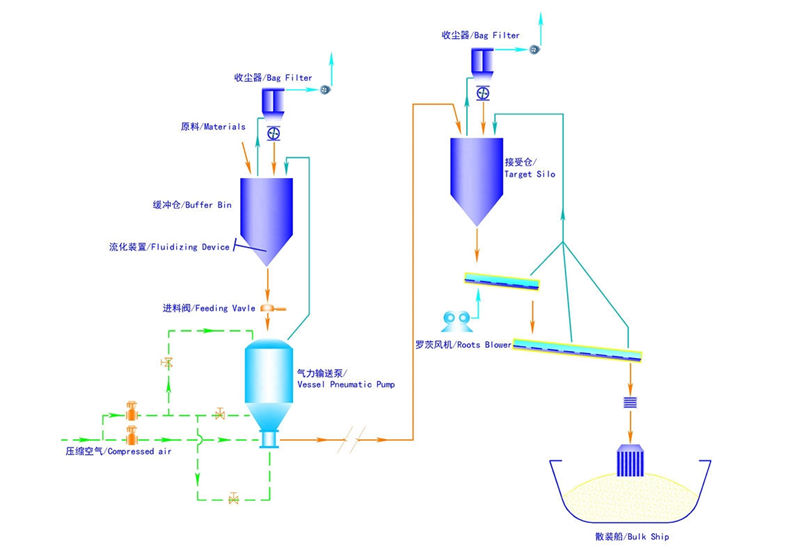

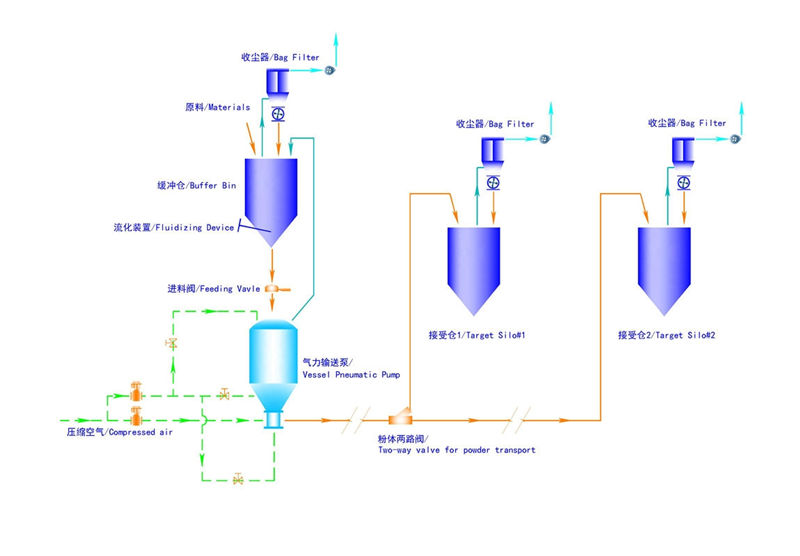

At present, our longest transmission horizontal distance of 2200m, the height of 30m; The maximum throughput of a single machine is 300 t/h; Conveying energy consumption < 3.8kWh/t·km, conveying straight pipe service life of more than 10 years, elbow service life of more than 3 years. According to the requirements of customers, according to the specifications and performance of powder materials provided by customers, transport distance, transport volume and geographical conditions and other parameters, specifically develop the best program of engineering design and equipment selection, such as including the calculation of air volume, the ratio of pipelines, receiving bin dust treatment and after-sales plans. Based on a large number of engineering practice experience, most positive pressure dense phase intermittent pneumatic conveying is mainly divided into the following three processes:

In terms of positive pressure dense phase intermittent pneumatic conveying, the company has always been committed to the theoretical research of pneumatic conveying system and the summary of engineering practical experience, focusing on breaking through the key technologies of long distance, large output, low energy consumption and low wear in the process of pneumatic conveying. The core products are PCD type positive pressure dense phase pneumatic conveying bin pump. At the same time to provide systematic, standardized, refined engineering design and technical services. According to the needs of different customers, we make the best design scheme according to the parameters of material nature, conveying distance, conveying capacity, receiving bin capacity, dust removal capacity and geographical conditions. Each equipment has passed the qualified inspection, and each pneumatic conveying system has its own design characteristics, so that customers can truly experience the intelligent management and economic benefits brought by advanced technology products.

At present, our longest transmission horizontal distance of 2200m, the height of 30m; The maximum throughput of a single machine is 300 t/h; Conveying energy consumption < 3.8kWh/t·km, conveying straight pipe service life of more than 10 years, elbow service life of more than 3 years. According to the requirements of customers, according to the specifications and performance of powder materials provided by customers, transport distance, transport volume and geographical conditions and other parameters, specifically develop the best program of engineering design and equipment selection, such as including the calculation of air volume, the ratio of pipelines, receiving bin dust treatment and after-sales plans. Based on a large number of engineering practice experience, most positive pressure dense phase intermittent pneumatic conveying is mainly divided into the following three processes: