PCD type positive pressure dense phase pneumatic conveying bin pump

Release date:2019-05-25 Views:912

PCD type positive pressure dense phase pneumatic conveying bin pump

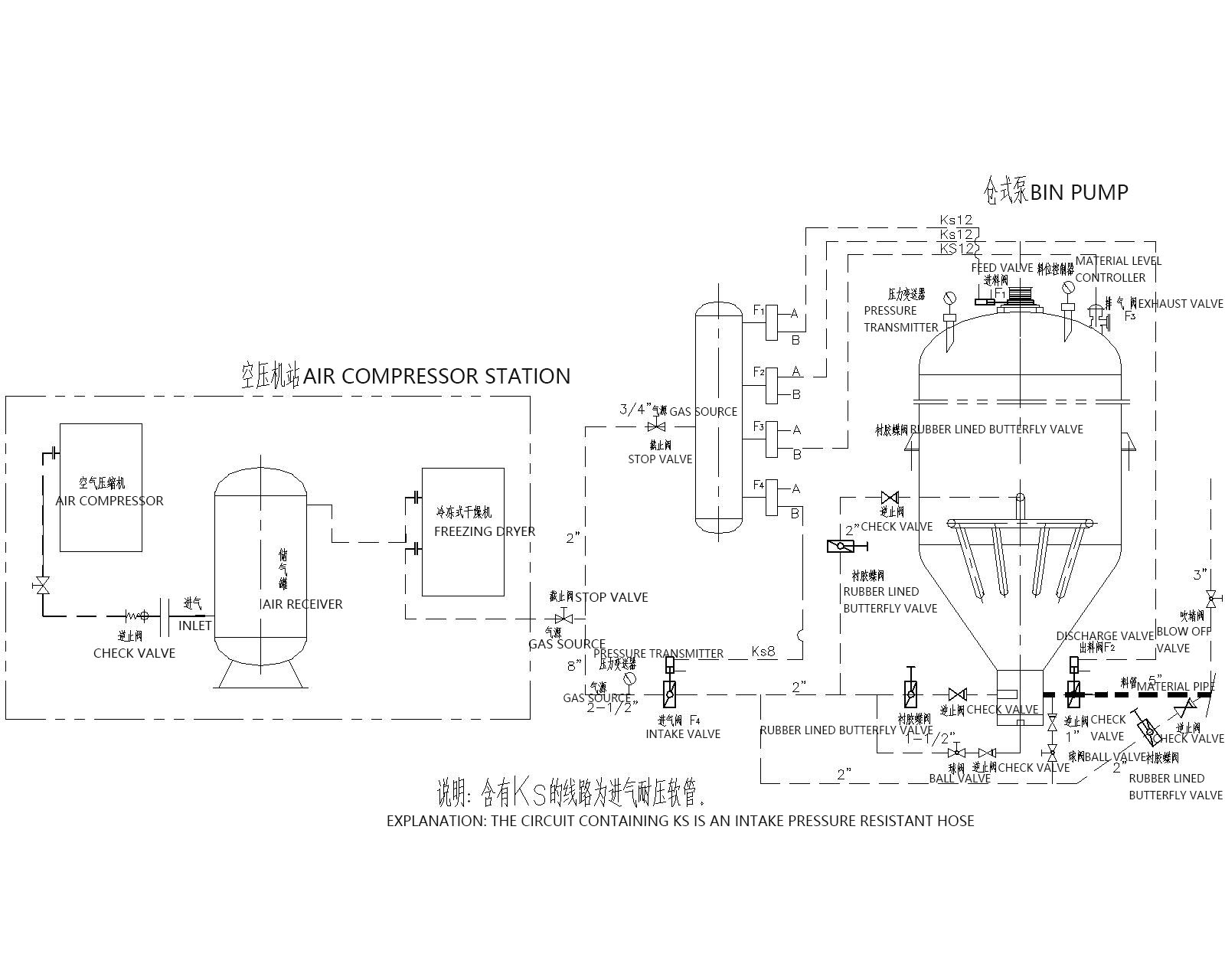

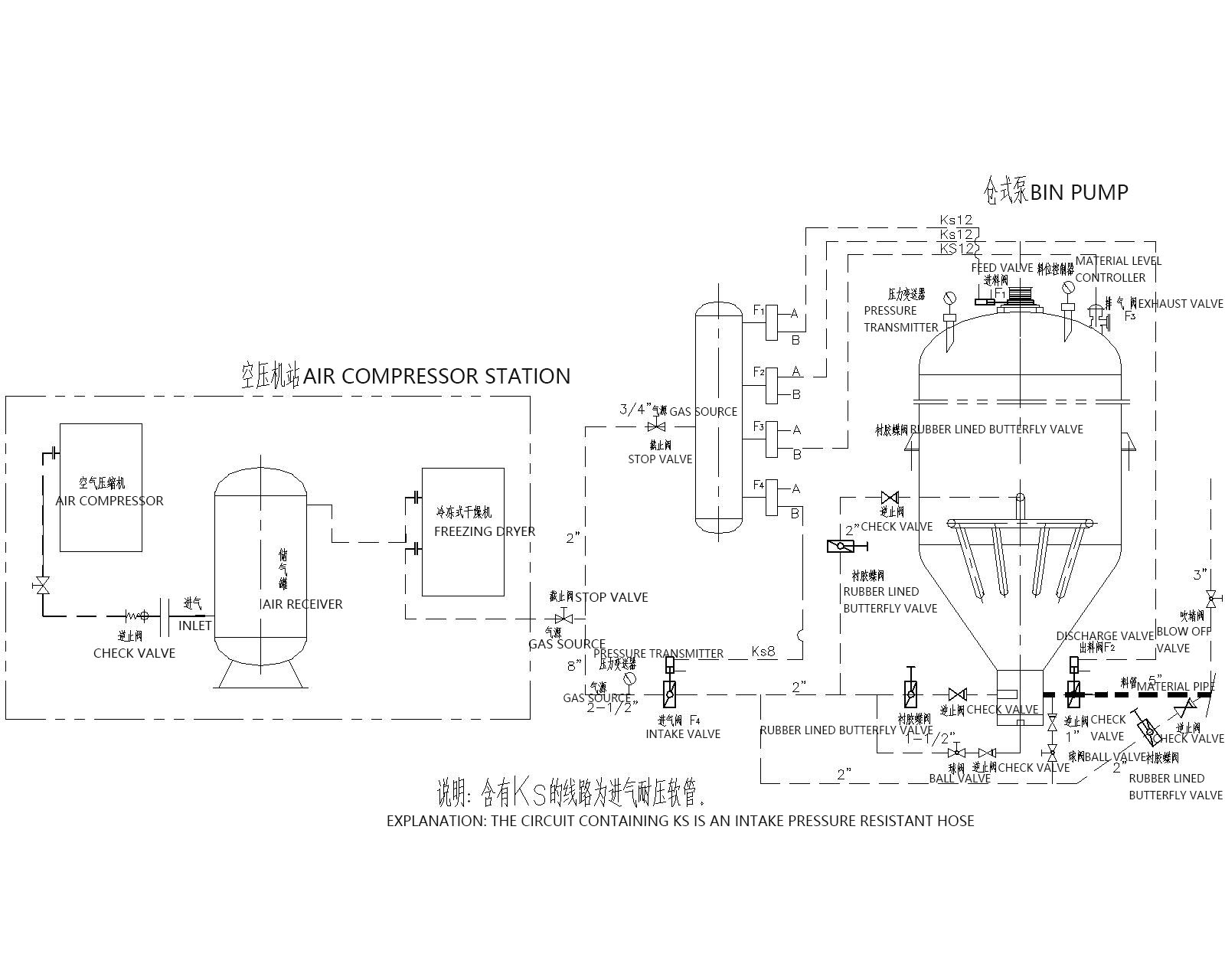

After years of research PCD positive pressure dense phase pneumatic conveying bin pump, combined with rich practical experience, our company has developed pneumatic conveying equipment and process system with independent intellectual property rights, and its main indicators have reached the international advanced level. According to the nature of the material to be transported, the particle size, the conveying distance and the conveying volume, the volume of the pump is determined, that is, the single machine design is carried out, so that the transportation energy consumption can be minimized under the premise of meeting the process requirements. According to the parameters, performance, conveying distance, conveying capacity and geographical conditions of the powder materials provided by the customer, we have developed the best solution for pneumatic conveying, including the calculation of air volume, the ratio of piping, the receiving dust collection and the after-sales plan and so on.

Main features of the product

①Large conveying capacity: >300t/h;

② Long distance: >2000m;

③Low power consumption: <3.8kWh/t·km;

④Low wear and tear: pipeline life > 10 years;

⑤ Low speed: initial speed 6 ~ 10m / s;

⑥High mixing ratio: >30kg/kg;

⑦Process lay-out is flexible, no dust, high operating rate, lower investment than mechanical transportation, less maintenance costs.

Application field

PCD pneumatic conveying equipment and system has been widely used in building materials, chemical industry, mining, power, metallurgy and other industries. The conveying materials are cement, raw material, fly ash, lime, dry discharged carbide slag, slag powder, steel slag powder, coal powder, alumina powder, bauxite powder, phosphorus powder, pyrophyllite powder and organic silicon powder.

Normal specification pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD18/N |

PCD20/N |

PCD22/N |

Reference transport distance |

|

|

Specification |

5.0~6.7m3 |

7.0~10.0m3 |

10.0~15.0m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

12~20 |

16~32 |

25~50 |

500 |

30 |

|

Fly ash |

0.75 |

18~32 |

25~48 |

35~70 |

50 |

|

|

|

Limestone powder / mineral powder |

0.8 |

20~35 |

26~51 |

38~75 |

500 |

30 |

|

|

Cement/raw material |

1.0 |

24~42 |

32~65 |

48~95 |

500 |

30 |

|

|

Silicon powder |

1.2 |

28~50 |

40~75 |

55~115 |

500 |

30 |

|

Small specification pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD08/M |

PCD10/M |

PCD12/M |

PCD14/M |

Reference transport distance |

|

|

Specification |

0.2~0.5m3 |

0.6~1.6m3 |

1.5~2.5m3 |

2.5~5.0m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

0.5~1.8 |

1.5~5.5 |

5.0~9.0 |

8.0~18.0 |

100 |

20 |

|

Fly ash |

0.75 |

0.9~2.8 |

2.5~8.5 |

7.0~14.0 |

12.0~27.0 |

100 |

20 |

|

|

Limestone powder / mineral powder |

0.8 |

1.0~3.0 |

3.0~9.0 |

8.0~15.0 |

12.0~28.0 |

100 |

20 |

|

|

Cement/raw material |

1.0 |

1.2~3.5 |

3.5~11.5 |

10.0~18.0 |

16.0~36.0 |

100 |

20 |

|

|

Silicon powder |

1.2 |

1.5~4.0 |

4.5~13.5 |

12.0~20.0 |

19.0~43.0 |

100 |

20 |

|

Long-distance pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD24/L |

PCD26/L |

PCD28/L |

PCD30/L |

Reference transport distance |

|

|

Specification |

16~20m3 |

18~22m3 |

20~27m3 |

26~32m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

20~40 |

25~45 |

30~55 |

45~65 |

1000 |

25 |

|

Fly ash |

0.75 |

35~60 |

45~65 |

45~80 |

65~95 |

1000 |

25 |

|

|

Limestone powder / mineral powder |

0.8 |

40~65 |

45~70 |

50~85 |

70~100 |

1000 |

25 |

|

|

Cement/raw material |

1.0 |

50~80 |

55~90 |

65~110 |

90~120 |

1000 |

25 |

|

Large conveying capacity pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD24/H |

PCD26/H |

PCD28/H |

PCD30/H |

Reference transport distance |

|

|

Specification |

16~20m3 |

18~22m3 |

20~27m3 |

26~32m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

50~80 |

60~90 |

65~110 |

80~130 |

200 |

20 |

|

Fly ash |

0.75 |

75~125 |

85~130 |

95~160 |

125~190 |

200 |

20 |

|

|

Limestone powder / mineral powder |

0.8 |

80~130 |

90~140 |

100~170 |

130~200 |

200 |

20 |

|

|

Cement/raw material |

1.0 |

100~150 |

115~175 |

130~215 |

165~260 |

200 |

20 |

|

PCD type positive pressure dense phase pneumatic conveying bin pump

After years of research PCD positive pressure dense phase pneumatic conveying bin pump, combined with rich practical experience, our company has developed pneumatic conveying equipment and process system with independent intellectual property rights, and its main indicators have reached the international advanced level. According to the nature of the material to be transported, the particle size, the conveying distance and the conveying volume, the volume of the pump is determined, that is, the single machine design is carried out, so that the transportation energy consumption can be minimized under the premise of meeting the process requirements. According to the parameters, performance, conveying distance, conveying capacity and geographical conditions of the powder materials provided by the customer, we have developed the best solution for pneumatic conveying, including the calculation of air volume, the ratio of piping, the receiving dust collection and the after-sales plan and so on.

Main features of the product

①Large conveying capacity: >300t/h;

② Long distance: >2000m;

③Low power consumption: <3.8kWh/t·km;

④Low wear and tear: pipeline life > 10 years;

⑤ Low speed: initial speed 6 ~ 10m / s;

⑥High mixing ratio: >30kg/kg;

⑦Process lay-out is flexible, no dust, high operating rate, lower investment than mechanical transportation, less maintenance costs.

Application field

PCD pneumatic conveying equipment and system has been widely used in building materials, chemical industry, mining, power, metallurgy and other industries. The conveying materials are cement, raw material, fly ash, lime, dry discharged carbide slag, slag powder, steel slag powder, coal powder, alumina powder, bauxite powder, phosphorus powder, pyrophyllite powder and organic silicon powder.

Normal specification pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD18/N |

PCD20/N |

PCD22/N |

Reference transport distance |

|

|

Specification |

5.0~6.7m3 |

7.0~10.0m3 |

10.0~15.0m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

12~20 |

16~32 |

25~50 |

500 |

30 |

|

Fly ash |

0.75 |

18~32 |

25~48 |

35~70 |

50 |

|

|

|

Limestone powder / mineral powder |

0.8 |

20~35 |

26~51 |

38~75 |

500 |

30 |

|

|

Cement/raw material |

1.0 |

24~42 |

32~65 |

48~95 |

500 |

30 |

|

|

Silicon powder |

1.2 |

28~50 |

40~75 |

55~115 |

500 |

30 |

|

Small specification pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD08/M |

PCD10/M |

PCD12/M |

PCD14/M |

Reference transport distance |

|

|

Specification |

0.2~0.5m3 |

0.6~1.6m3 |

1.5~2.5m3 |

2.5~5.0m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

0.5~1.8 |

1.5~5.5 |

5.0~9.0 |

8.0~18.0 |

100 |

20 |

|

Fly ash |

0.75 |

0.9~2.8 |

2.5~8.5 |

7.0~14.0 |

12.0~27.0 |

100 |

20 |

|

|

Limestone powder / mineral powder |

0.8 |

1.0~3.0 |

3.0~9.0 |

8.0~15.0 |

12.0~28.0 |

100 |

20 |

|

|

Cement/raw material |

1.0 |

1.2~3.5 |

3.5~11.5 |

10.0~18.0 |

16.0~36.0 |

100 |

20 |

|

|

Silicon powder |

1.2 |

1.5~4.0 |

4.5~13.5 |

12.0~20.0 |

19.0~43.0 |

100 |

20 |

|

Long-distance pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD24/L |

PCD26/L |

PCD28/L |

PCD30/L |

Reference transport distance |

|

|

Specification |

16~20m3 |

18~22m3 |

20~27m3 |

26~32m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

20~40 |

25~45 |

30~55 |

45~65 |

1000 |

25 |

|

Fly ash |

0.75 |

35~60 |

45~65 |

45~80 |

65~95 |

1000 |

25 |

|

|

Limestone powder / mineral powder |

0.8 |

40~65 |

45~70 |

50~85 |

70~100 |

1000 |

25 |

|

|

Cement/raw material |

1.0 |

50~80 |

55~90 |

65~110 |

90~120 |

1000 |

25 |

|

Large conveying capacity pneumatic conveying bin pump parameter table

|

Conveying material |

Bulk weight (t/m3) |

Model |

PCD24/H |

PCD26/H |

PCD28/H |

PCD30/H |

Reference transport distance |

|

|

Specification |

16~20m3 |

18~22m3 |

20~27m3 |

26~32m3 |

Horizontal (m) |

Vertical (m) |

||

|

Pulverized coal |

0.5 |

Delivery volume (t/h) |

50~80 |

60~90 |

65~110 |

80~130 |

200 |

20 |

|

Fly ash |

0.75 |

75~125 |

85~130 |

95~160 |

125~190 |

200 |

20 |

|

|

Limestone powder / mineral powder |

0.8 |

80~130 |

90~140 |

100~170 |

130~200 |

200 |

20 |

|

|

Cement/raw material |

1.0 |

100~150 |

115~175 |

130~215 |

165~260 |

200 |

20 |

|