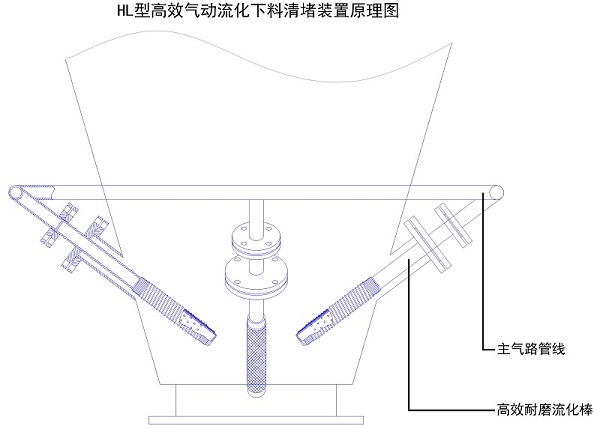

HL type high efficiency pneumatic fluidized blanking device

Release date:2019-05-23 Views:856

HL type high efficiency pneumatic fluidized blanking device

Working principle: The high-efficiency pneumatic fluidized blanking device uses the compressed air provided by the air compressor as the power. According to different material properties, the amount of discharge, the degree of fluidization, etc., it will be compressed by the pressure reducing valve. The air pressure is controlled at 40 kPa to 0.4 MPa.

This product is used to remove all kinds of silos from the wall. The system solves the problem of shed material by reducing the friction between the material and the wall of the warehouse to solve the problem of material sticking and material clogging, and using the airflow to dissipate the material to break the stress balance of the arch.

①For the viscous material, the arching can be realized. The more viscous materials are stored in the steel silo and are easily bonded together to form an arch. Mechanical equipment (such as a spiral reamer to break the arch) is required, which is difficult to operate. The high-efficiency pneumatic fluidized blanking and plugging device can adopt the first pulsed continuous fluidization to realize the arching and discharging. For long-term storage materials, the high-efficiency pneumatic fluidized blanking and plugging device is used to periodically fluidize the materials in the storage tank before the materials are completely compacted, which can effectively prevent material arching and improve the fluidity of the materials. The principle of natural weight is discharged.

② Anti-skinning discharge can be achieved for materials with large moisture content. The moisture content of the material is easy to crust in the steel silo, and it is easy to form agglomerates (not agglomerated), which is difficult to cut, and sometimes the mechanical vibration effect of the taper is not obvious. The high-efficiency pneumatic fluidized blanking device is inserted into the steel silo cone, and is heated and compressed to inflate and spray, which can prevent anti-skinning and broken aggregate discharge. After fluidization, the loose material passes through the steel silo. The lower feed port flows out, and part of the compressed gas passes through the material layer and is discharged by the top dust collector. The circulation of the air maintains the fluidity of the material, increases the smoothness of the blanking, and can also take away part of the water to play the role of drying the material.

Main features of the product

1. It can completely remove the storage bin to block the shed, ensure the smooth flow of industrial production, and improve the operation rate of industrial production;

2.It can improve the effective volume utilization rate of the storage bin and effectively adjust the balance of industrial raw materials or finished materials in the production process, thereby improving the quality and efficiency of industrial production;

3.The structure is simple, the work is reliable, the operation is convenient, and the clearing can be unblocked every time the clearance is not more than 9 seconds;

4.Newly built mineral warehouses and old warehouses suitable for steel warehouses and Kamakura structures;

5.Applicable to materials with different particle size and high water content, for clearing and arching;

6.Completely avoid the personal injury caused by manual clearing and arching, and the equipment damage caused by the clearing of the guns, economic and social benefits are very obvious.

7. Wide range of pressure regulation: According to the characteristics of the material, the fluidization pressure is adjustable between 40kPa and 0.4MPa;

8. Low gas consumption: 0.4 m3/min~2 m3/min;

9. Flexible layout: according to the height of the cone, there are single layers and multiple layers;

10. Fluidization mode: pulsed, continuous, automatic setting, simple and safe operation;

11.Economic and environmental protection: lower investment than mechanical transportation, low maintenance costs, no dust;

Application field

1.Metal mine concentrator: clearing of the original mine silo and mine silo;

2.Non-metallic mine concentrator: clearing of various raw ore warehouses and mine powder bins;

3.he clearing of the hyperbolic raw coal bunker and pulverized coal bunker of the thermal power plant;

4. Clearance of raw material warehouses and finished material warehouses in iron and steel plants, cement plants, coal mines, etc.

Widely used in various cement silos, fly ash silos, slaked lime silos, dry calcined carbide, slag silos, silicone silos, pulverized coal silos, alumina silos, vanadium ore silos, heavy calcium micro-powders and other granular materials Storage and storage, etc.

HL type high efficiency pneumatic fluidized blanking clearing device

|

Specification model |

Gas consumption (m3/min) |

warehouse cone diameter (m) |

Fluidized discharge volume (t/h) |

Applicable warehouse cone angle

|

|

HL-4 |

0.4~0.6 m3/min |

≤Ф3.0 |

40~60 |

40°~72° Note: The larger the angle of the warehouse cone, the flatter the warehouse cone, the larger the size of the equipment and the amount of compressed air consumed. |

|

HL-6 |

0.6~0.9 m3/min |

Ф3.0~Ф5.0 |

60~100 |

|

|

HL-8 |

0.8~1.2 m3/min |

Ф5.0~Ф8.0 |

80~120 |

|

|

HL-10 |

1.0~1.5 m3/min |

Ф8.0~Ф12.0 |

100~150 |

|

|

HL-12 |

1.2~1.8 m3/min |

Ф12.0~Ф16.0 |

120~200 |

|

|

HL-14 |

1.4~2.0 m3/min |

≥Ф16.0 |

≥200 |

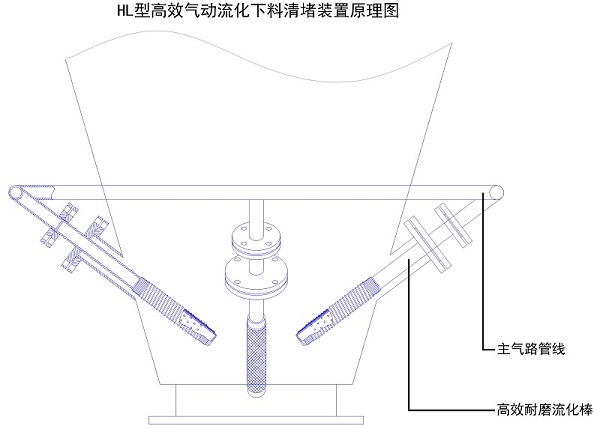

HL type high efficiency pneumatic fluidized blanking device

Working principle: The high-efficiency pneumatic fluidized blanking device uses the compressed air provided by the air compressor as the power. According to different material properties, the amount of discharge, the degree of fluidization, etc., it will be compressed by the pressure reducing valve. The air pressure is controlled at 40 kPa to 0.4 MPa.

This product is used to remove all kinds of silos from the wall. The system solves the problem of shed material by reducing the friction between the material and the wall of the warehouse to solve the problem of material sticking and material clogging, and using the airflow to dissipate the material to break the stress balance of the arch.

①For the viscous material, the arching can be realized. The more viscous materials are stored in the steel silo and are easily bonded together to form an arch. Mechanical equipment (such as a spiral reamer to break the arch) is required, which is difficult to operate. The high-efficiency pneumatic fluidized blanking and plugging device can adopt the first pulsed continuous fluidization to realize the arching and discharging. For long-term storage materials, the high-efficiency pneumatic fluidized blanking and plugging device is used to periodically fluidize the materials in the storage tank before the materials are completely compacted, which can effectively prevent material arching and improve the fluidity of the materials. The principle of natural weight is discharged.

② Anti-skinning discharge can be achieved for materials with large moisture content. The moisture content of the material is easy to crust in the steel silo, and it is easy to form agglomerates (not agglomerated), which is difficult to cut, and sometimes the mechanical vibration effect of the taper is not obvious. The high-efficiency pneumatic fluidized blanking device is inserted into the steel silo cone, and is heated and compressed to inflate and spray, which can prevent anti-skinning and broken aggregate discharge. After fluidization, the loose material passes through the steel silo. The lower feed port flows out, and part of the compressed gas passes through the material layer and is discharged by the top dust collector. The circulation of the air maintains the fluidity of the material, increases the smoothness of the blanking, and can also take away part of the water to play the role of drying the material.

Main features of the product

1. It can completely remove the storage bin to block the shed, ensure the smooth flow of industrial production, and improve the operation rate of industrial production;

2.It can improve the effective volume utilization rate of the storage bin and effectively adjust the balance of industrial raw materials or finished materials in the production process, thereby improving the quality and efficiency of industrial production;

3.The structure is simple, the work is reliable, the operation is convenient, and the clearing can be unblocked every time the clearance is not more than 9 seconds;

4.Newly built mineral warehouses and old warehouses suitable for steel warehouses and Kamakura structures;

5.Applicable to materials with different particle size and high water content, for clearing and arching;

6.Completely avoid the personal injury caused by manual clearing and arching, and the equipment damage caused by the clearing of the guns, economic and social benefits are very obvious.

7. Wide range of pressure regulation: According to the characteristics of the material, the fluidization pressure is adjustable between 40kPa and 0.4MPa;

8. Low gas consumption: 0.4 m3/min~2 m3/min;

9. Flexible layout: according to the height of the cone, there are single layers and multiple layers;

10. Fluidization mode: pulsed, continuous, automatic setting, simple and safe operation;

11.Economic and environmental protection: lower investment than mechanical transportation, low maintenance costs, no dust;

Application field

1.Metal mine concentrator: clearing of the original mine silo and mine silo;

2.Non-metallic mine concentrator: clearing of various raw ore warehouses and mine powder bins;

3.he clearing of the hyperbolic raw coal bunker and pulverized coal bunker of the thermal power plant;

4. Clearance of raw material warehouses and finished material warehouses in iron and steel plants, cement plants, coal mines, etc.

Widely used in various cement silos, fly ash silos, slaked lime silos, dry calcined carbide, slag silos, silicone silos, pulverized coal silos, alumina silos, vanadium ore silos, heavy calcium micro-powders and other granular materials Storage and storage, etc.

HL type high efficiency pneumatic fluidized blanking clearing device

|

Specification model |

Gas consumption (m3/min) |

warehouse cone diameter (m) |

Fluidized discharge volume (t/h) |

Applicable warehouse cone angle

|

|

HL-4 |

0.4~0.6 m3/min |

≤Ф3.0 |

40~60 |

40°~72° Note: The larger the angle of the warehouse cone, the flatter the warehouse cone, the larger the size of the equipment and the amount of compressed air consumed. |

|

HL-6 |

0.6~0.9 m3/min |

Ф3.0~Ф5.0 |

60~100 |

|

|

HL-8 |

0.8~1.2 m3/min |

Ф5.0~Ф8.0 |

80~120 |

|

|

HL-10 |

1.0~1.5 m3/min |

Ф8.0~Ф12.0 |

100~150 |

|

|

HL-12 |

1.2~1.8 m3/min |

Ф12.0~Ф16.0 |

120~200 |

|

|

HL-14 |

1.4~2.0 m3/min |

≥Ф16.0 |

≥200 |