Grinding materials with different product fineness requirements

Release date:2023-06-15 Views:1284

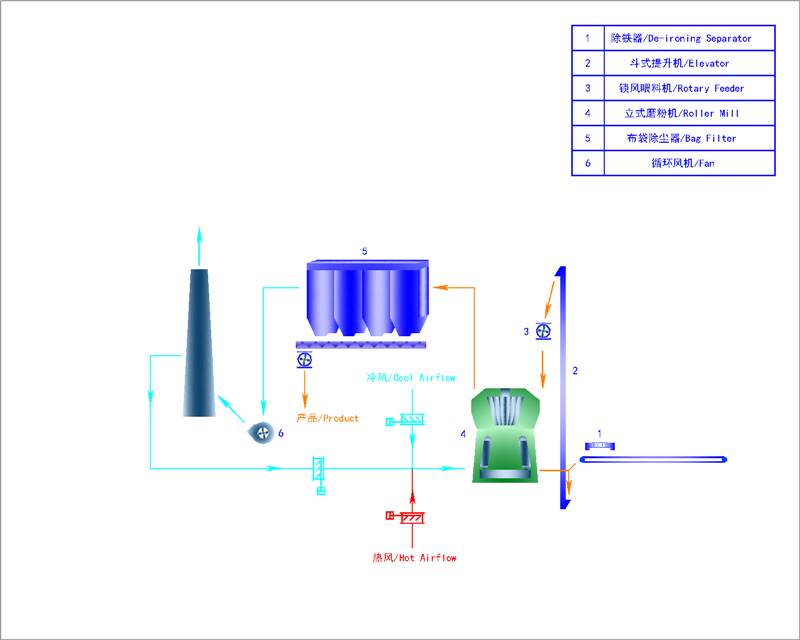

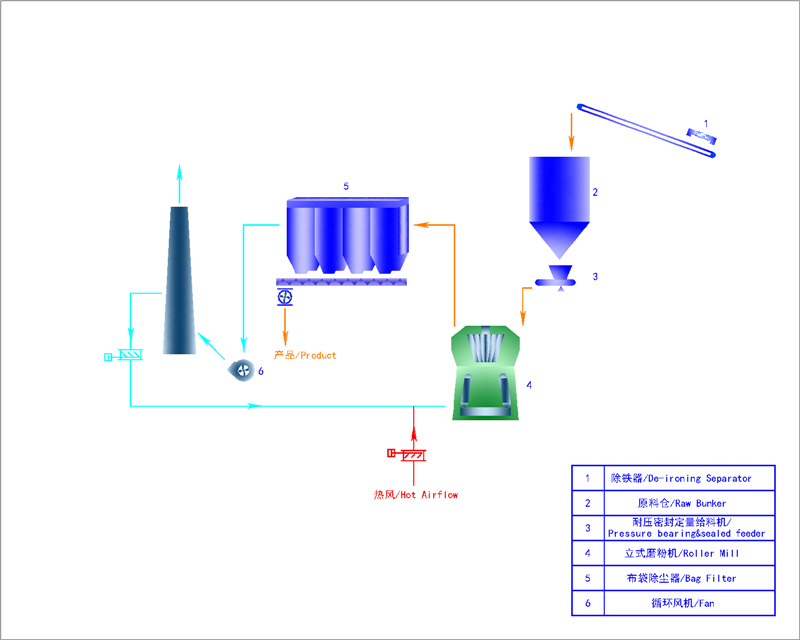

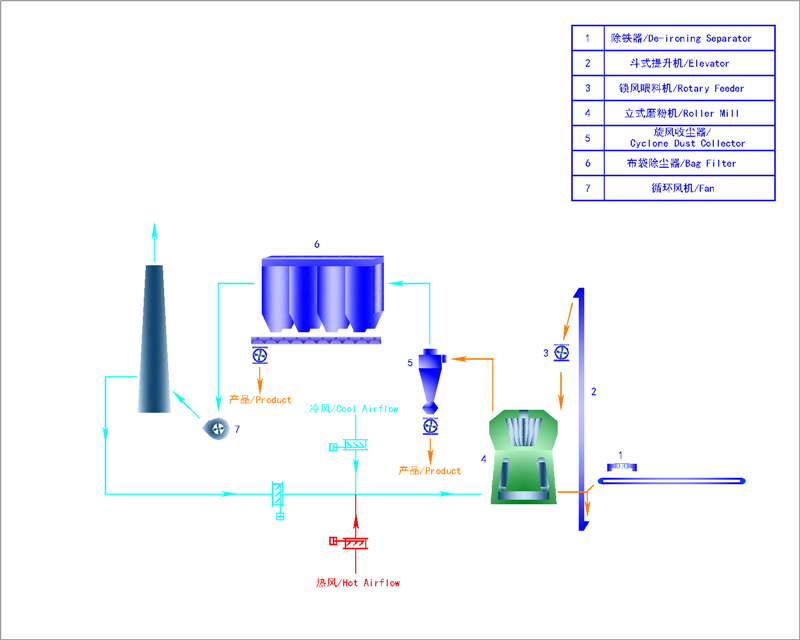

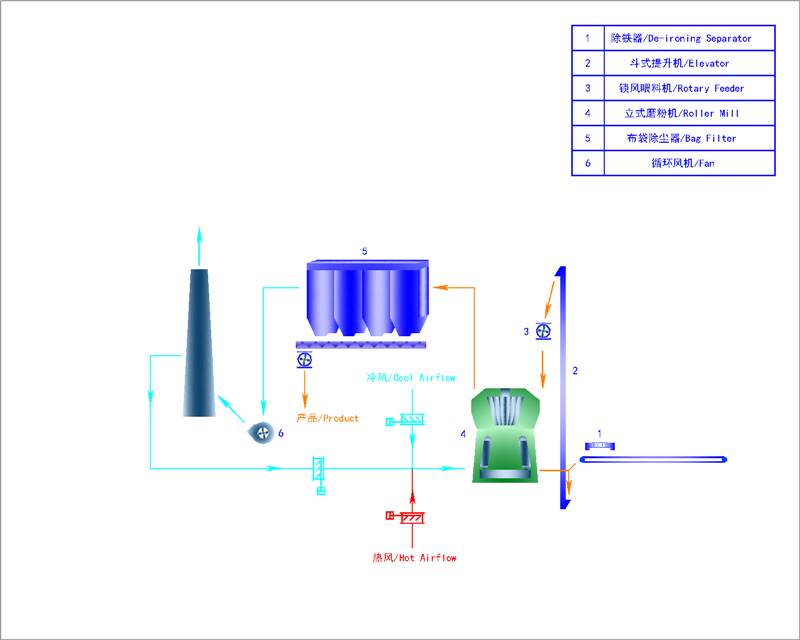

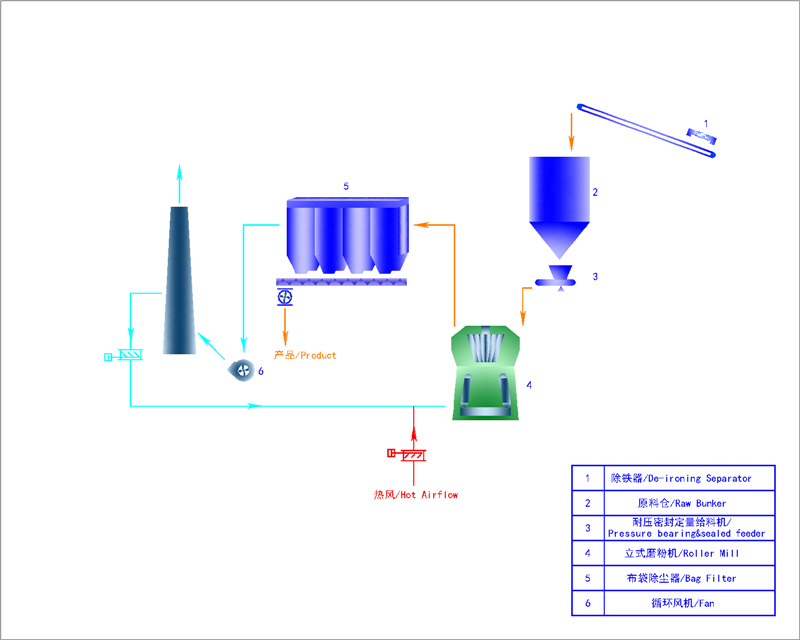

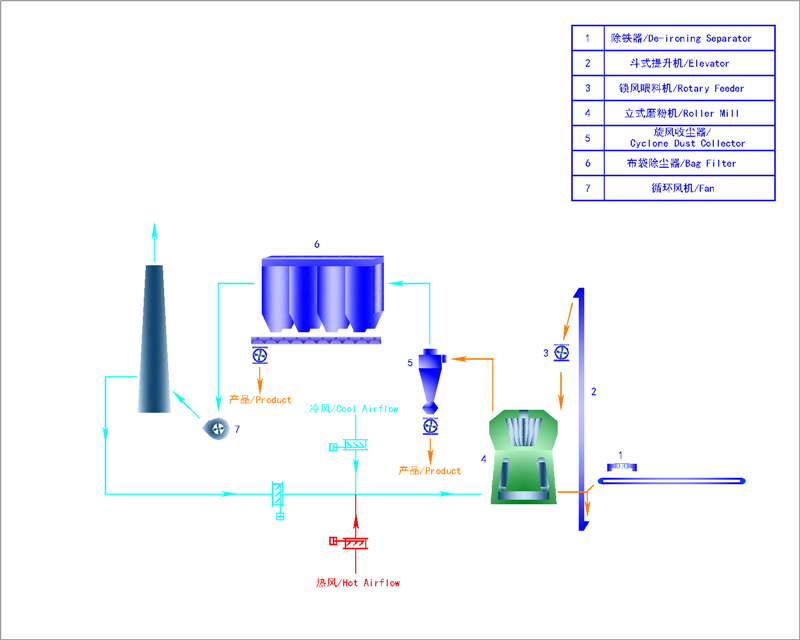

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can produce both coarse powder and ultrafine powder, and can produce materials with different product fineness requirements, ranging from 2-5mm coarse powder (such as shale in the new wall material industry, sand in the construction industry, etc.) to 15 micron ultra-fine powder with a pass rate of 97% (such as heavy calcium powder in the paper industry and activated carbon ultra-fine powder in the chemical industry). The product fineness adjustment has strong flexibility and a wide range of applications.

Solution

For the production of coarse powder, when selecting a vertical mill, it is necessary to use a powder selection machine structure with low resistance and wear resistance. It is not advisable to use a powder selection machine with high blade density and complex rotor structure, which will cause unnecessary investment and increased production and maintenance costs. At the same time, due to the large number of particles, necessary anti-wear treatment and structural design of the powder selection machine need to be carried out to achieve reasonable powder selection output and energy consumption;

For the production of ultra-fine powder, the selection of vertical mills should focus on the design and optimization of the powder selection machine. Due to the high resistance of powder selection at this time, it is necessary to strictly control the fineness, prevent large particles from running coarse, excessive wear of blades, and abnormal vibration caused by high internal resistance in the mill. Therefore, for materials with different product fineness requirements, it is necessary to calculate and analyze the flow field of materials and gas in the vertical mill, especially in the powder selection machine, based on the characteristics of the materials, in order to determine a reasonable structure of the powder selection machine (such as the form of the rotor and the number and angle of the blades, the number and angle of the static blades), and at the same time, necessary auxiliary measures should be taken to control (such as using a sealing fan for gas sealing and forcibly controlling the coarsening of large particles).

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can produce both coarse powder and ultrafine powder, and can produce materials with different product fineness requirements, ranging from 2-5mm coarse powder (such as shale in the new wall material industry, sand in the construction industry, etc.) to 15 micron ultra-fine powder with a pass rate of 97% (such as heavy calcium powder in the paper industry and activated carbon ultra-fine powder in the chemical industry). The product fineness adjustment has strong flexibility and a wide range of applications.

Solution

For the production of coarse powder, when selecting a vertical mill, it is necessary to use a powder selection machine structure with low resistance and wear resistance. It is not advisable to use a powder selection machine with high blade density and complex rotor structure, which will cause unnecessary investment and increased production and maintenance costs. At the same time, due to the large number of particles, necessary anti-wear treatment and structural design of the powder selection machine need to be carried out to achieve reasonable powder selection output and energy consumption;

For the production of ultra-fine powder, the selection of vertical mills should focus on the design and optimization of the powder selection machine. Due to the high resistance of powder selection at this time, it is necessary to strictly control the fineness, prevent large particles from running coarse, excessive wear of blades, and abnormal vibration caused by high internal resistance in the mill. Therefore, for materials with different product fineness requirements, it is necessary to calculate and analyze the flow field of materials and gas in the vertical mill, especially in the powder selection machine, based on the characteristics of the materials, in order to determine a reasonable structure of the powder selection machine (such as the form of the rotor and the number and angle of the blades, the number and angle of the static blades), and at the same time, necessary auxiliary measures should be taken to control (such as using a sealing fan for gas sealing and forcibly controlling the coarsening of large particles).

- Prev:None

- Next:Grinding materials with different moisture contents