Grinding materials with different moisture contents

Release date:2023-06-15 Views:1217

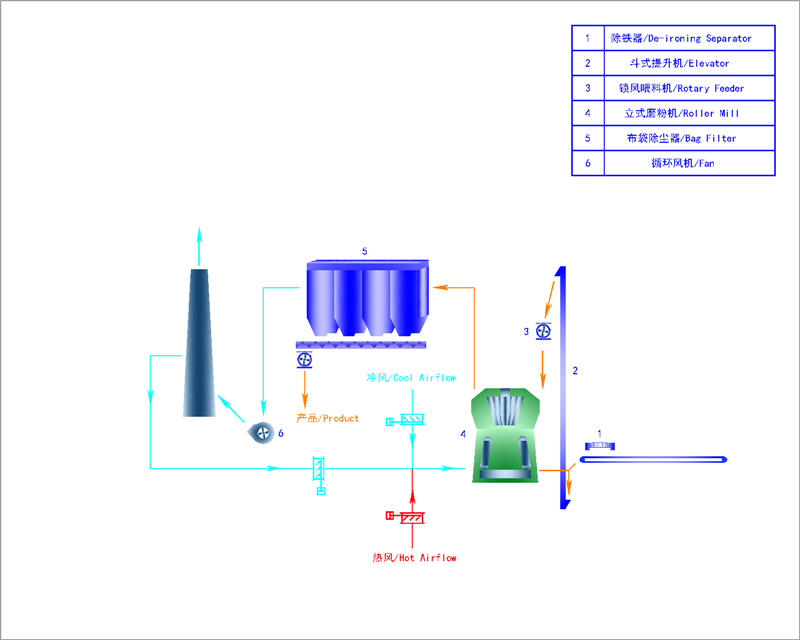

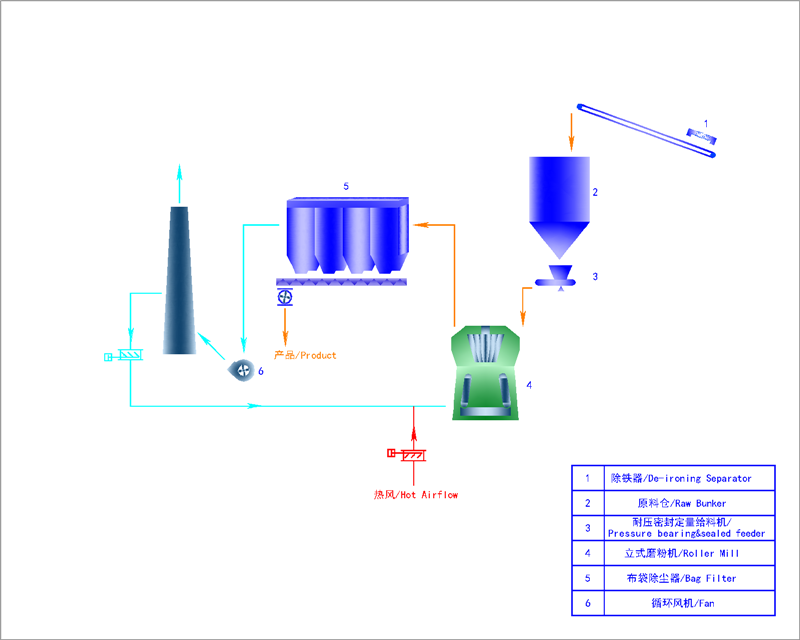

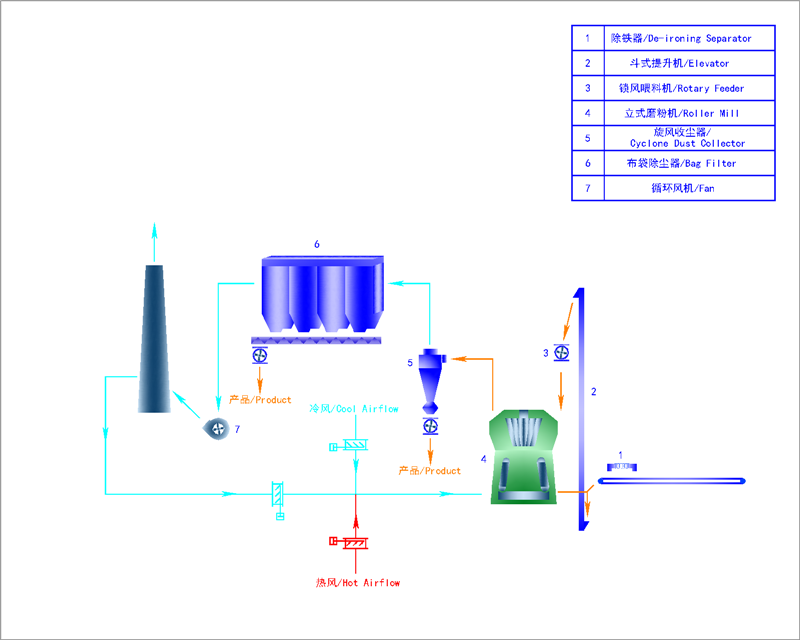

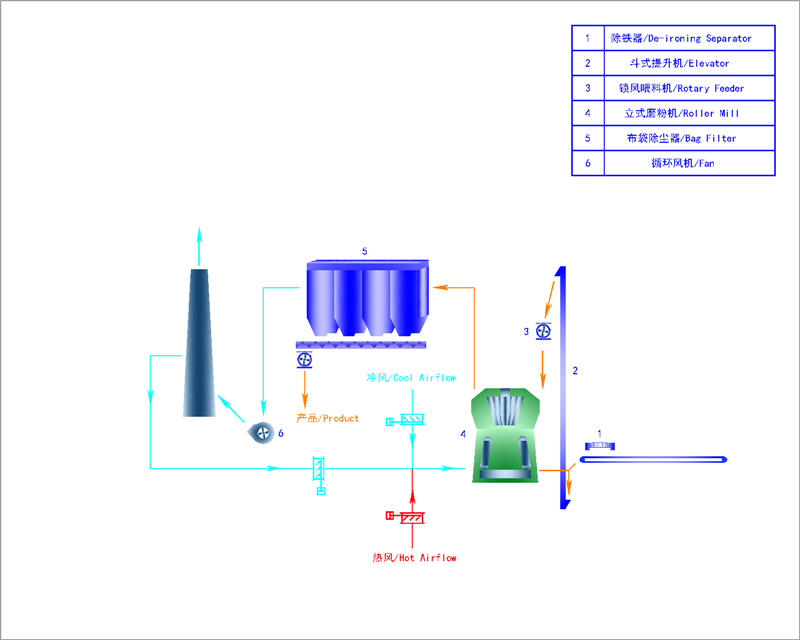

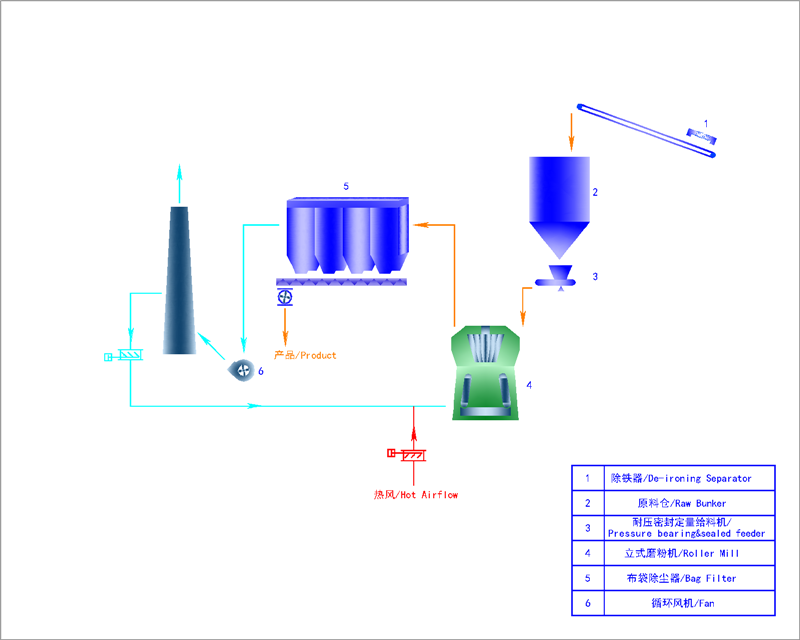

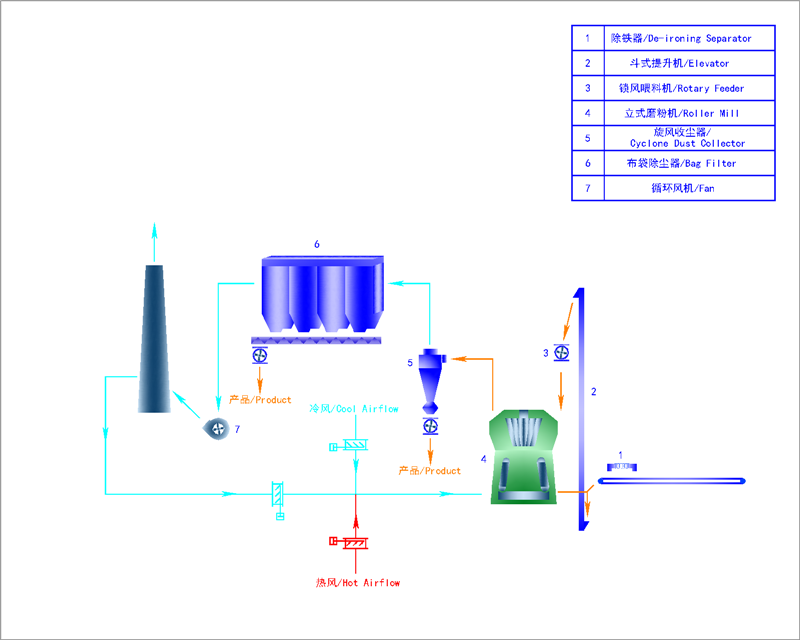

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can handle materials with high water content ranging from 20% to 30% (such as calcium carbide slag, brown coal, etc.) to materials with water content less than 1% (such as cement clinker, etc.), and has strong adaptability to the moisture content of the materials.

Solution

For the treatment of high moisture materials, there is a high demand for the drying capacity of vertical mills. The drying capacity of vertical mills should be an important direction for equipment selection. Through the thermal balance calculation of the vertical mill process system, the grinding, drying, and powder selection abilities of vertical mills should be scientifically and reasonably matched. On the premise of ensuring that the materials meet the drying requirements, the grinding and powder selection output should be maximized to achieve reliable, efficient, and energy-saving equipment selection;

For the treatment of low moisture materials, due to the fact that the vertical mill is essentially a bed mill, when the moisture content of the incoming material is too low, it is difficult for the material to form a stable material layer on the grinding disc after entering the vertical mill, which can cause abnormal vibration and unstable operation of the vertical mill. In order to ensure the stable operation of the vertical mill, it is necessary to solve the problem of how to stabilize the material layer. The general measures that can be taken include active measures (such as controlling and adjusting the thickness of the material layer, grinding pressure, height of the material retaining ring, slag discharge amount, etc.) and passive measures (such as adding a water spray device, etc.), while prioritizing the grinding capacity, reasonably considering the powder selection ability of the vertical mill.

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can handle materials with high water content ranging from 20% to 30% (such as calcium carbide slag, brown coal, etc.) to materials with water content less than 1% (such as cement clinker, etc.), and has strong adaptability to the moisture content of the materials.

Solution

For the treatment of high moisture materials, there is a high demand for the drying capacity of vertical mills. The drying capacity of vertical mills should be an important direction for equipment selection. Through the thermal balance calculation of the vertical mill process system, the grinding, drying, and powder selection abilities of vertical mills should be scientifically and reasonably matched. On the premise of ensuring that the materials meet the drying requirements, the grinding and powder selection output should be maximized to achieve reliable, efficient, and energy-saving equipment selection;

For the treatment of low moisture materials, due to the fact that the vertical mill is essentially a bed mill, when the moisture content of the incoming material is too low, it is difficult for the material to form a stable material layer on the grinding disc after entering the vertical mill, which can cause abnormal vibration and unstable operation of the vertical mill. In order to ensure the stable operation of the vertical mill, it is necessary to solve the problem of how to stabilize the material layer. The general measures that can be taken include active measures (such as controlling and adjusting the thickness of the material layer, grinding pressure, height of the material retaining ring, slag discharge amount, etc.) and passive measures (such as adding a water spray device, etc.), while prioritizing the grinding capacity, reasonably considering the powder selection ability of the vertical mill.