Grinding materials with different grindability

Release date:2023-06-15 Views:1221

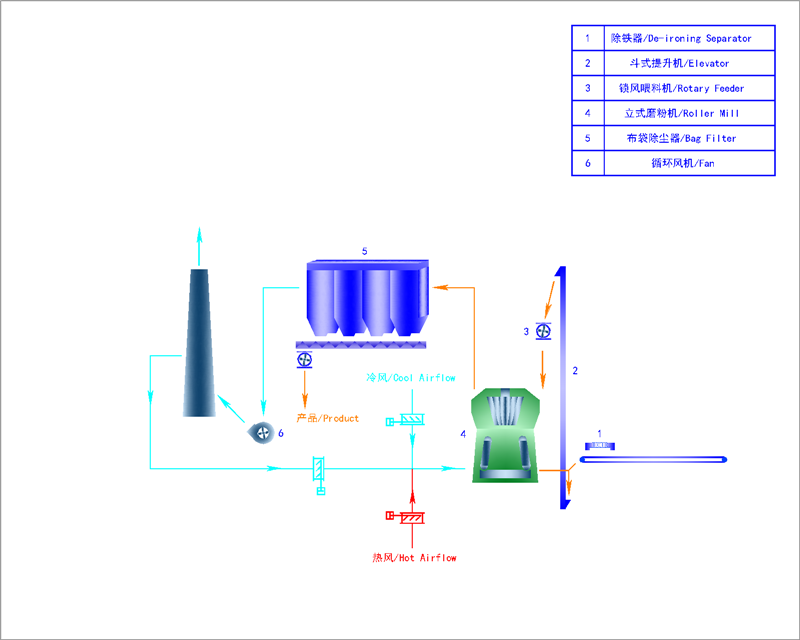

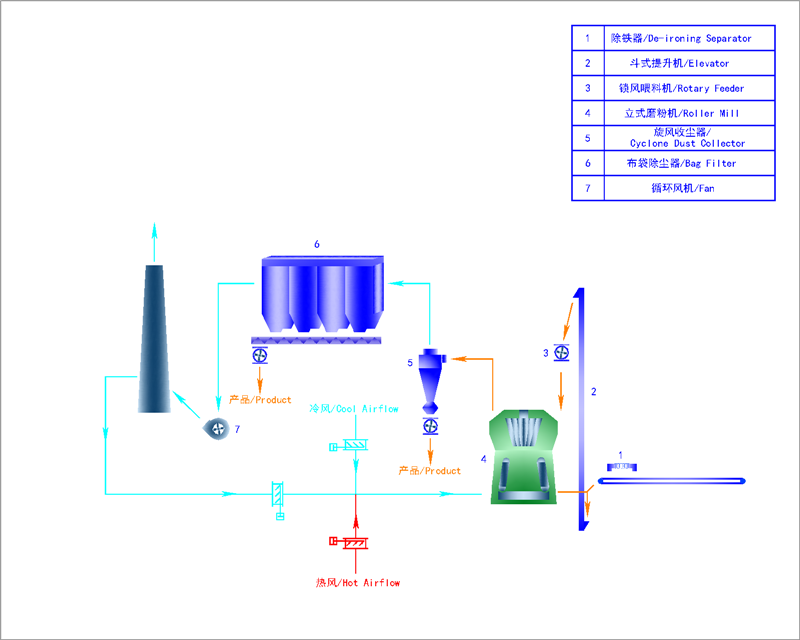

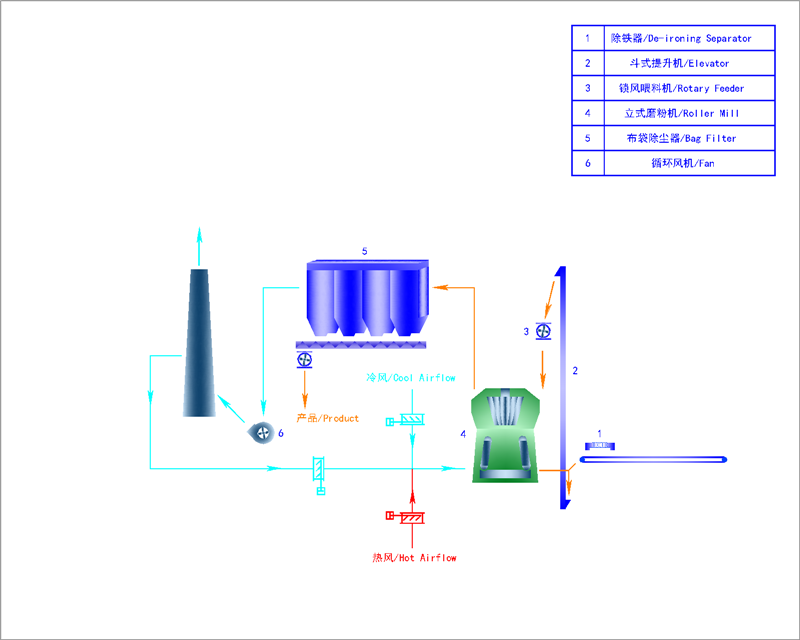

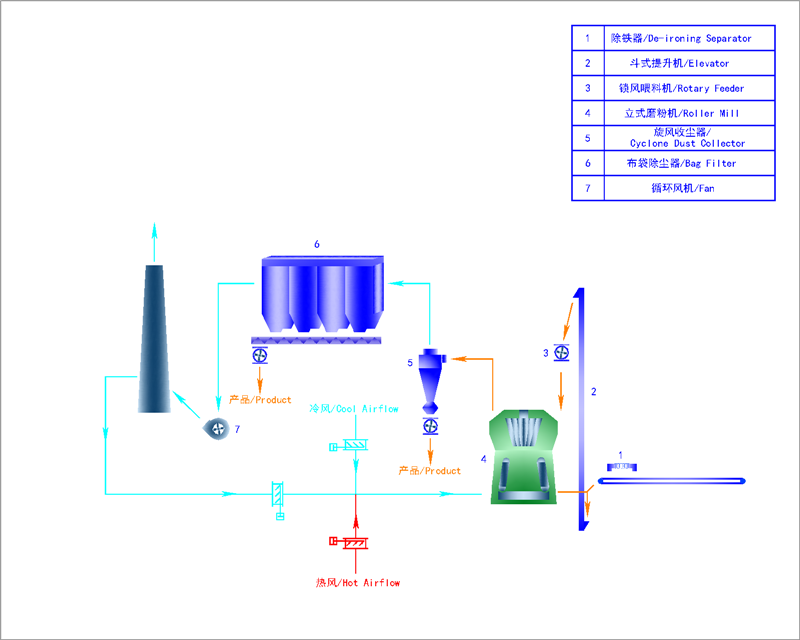

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can handle materials with good grindability or low hardness (such as clay, gypsum, lime, limestone, etc.), as well as materials with poor grindability or high hardness (such as quartz sand, steel slag, slag, pyroxene, kaolin, organic silicon, iron ore, etc.).

Solution

For materials with good grindability or low hardness, it is easy to overlook some details when selecting equipment due to the good grindability of the materials. Vertical grinding is an efficient grinding equipment that integrates three functions: grinding, drying, and powder selection. When dealing with extremely easy to grind materials (such as desulfurization stone paste), the grinding and powder selection capabilities of the same specification of vertical grinding are significantly different. At this time, the originally matched powder selection machine cannot meet the required powder selection amount for the existing grinding output. If the original equipment selection is still used at this time, due to the limitation of powder selection ability, although the grinding output is large, it is still unable to select qualified products in a timely manner, resulting in low output of the vertical mill, manifested as long-term high energy consumption and uneconomical operation. Therefore, it is necessary to consider how to achieve the optimal balance between the grinding output and powder selection output of the vertical mill. Theoretical calculations should be conducted based on engineering experience. When selecting equipment, both the grinding output and powder selection output should be considered simultaneously, and customized equipment selection should be carried out (such as using the original vertical mill body with a larger powder selection machine) to achieve economic and reasonable equipment selection;

For materials with poor grindability or high hardness, significant wear usually occurs during material grinding, and due to the use of high grinding pressure, the reliability of hydraulic components deteriorates. Therefore, when selecting equipment, the key consideration is how to handle the issue of wear resistance. In addition to using high wear-resistant materials for the main wear parts, necessary wear resistance measures should also be taken for the parts or components involved in wear. At the same time, hydraulic components that can withstand high grinding pressure should be selected.

In terms of grinding system, targeted, mature, reliable, safe and efficient grinding technology and supporting equipment have been developed for different physical and chemical characteristics of materials in various industries and types, such as moisture content, grindability, product fineness, and safety. The core equipment is the HVM vertical mill, which processes materials from high humidity to dry, from exceptionally difficult to grind to easy to grind, with product fineness ranging from coarse to fine, covering a wide range of fields, and a wide variety of materials being processed. Provide a scientific and reasonable complete process plan and equipment selection for the vertical grinding machine powder system, and provide an integrated powder processing solution. Based on a large amount of engineering practice experience, most powder processing is mainly divided into the following three process flows:

Scheme introduction

HVM vertical mill can handle materials with good grindability or low hardness (such as clay, gypsum, lime, limestone, etc.), as well as materials with poor grindability or high hardness (such as quartz sand, steel slag, slag, pyroxene, kaolin, organic silicon, iron ore, etc.).

Solution

For materials with good grindability or low hardness, it is easy to overlook some details when selecting equipment due to the good grindability of the materials. Vertical grinding is an efficient grinding equipment that integrates three functions: grinding, drying, and powder selection. When dealing with extremely easy to grind materials (such as desulfurization stone paste), the grinding and powder selection capabilities of the same specification of vertical grinding are significantly different. At this time, the originally matched powder selection machine cannot meet the required powder selection amount for the existing grinding output. If the original equipment selection is still used at this time, due to the limitation of powder selection ability, although the grinding output is large, it is still unable to select qualified products in a timely manner, resulting in low output of the vertical mill, manifested as long-term high energy consumption and uneconomical operation. Therefore, it is necessary to consider how to achieve the optimal balance between the grinding output and powder selection output of the vertical mill. Theoretical calculations should be conducted based on engineering experience. When selecting equipment, both the grinding output and powder selection output should be considered simultaneously, and customized equipment selection should be carried out (such as using the original vertical mill body with a larger powder selection machine) to achieve economic and reasonable equipment selection;

For materials with poor grindability or high hardness, significant wear usually occurs during material grinding, and due to the use of high grinding pressure, the reliability of hydraulic components deteriorates. Therefore, when selecting equipment, the key consideration is how to handle the issue of wear resistance. In addition to using high wear-resistant materials for the main wear parts, necessary wear resistance measures should also be taken for the parts or components involved in wear. At the same time, hydraulic components that can withstand high grinding pressure should be selected.

- Prev:Grinding materials with different moisture contents

- Next:None