HVM vertical mill

Release date:2019-07-19 Views:1018

HVM vertical mill

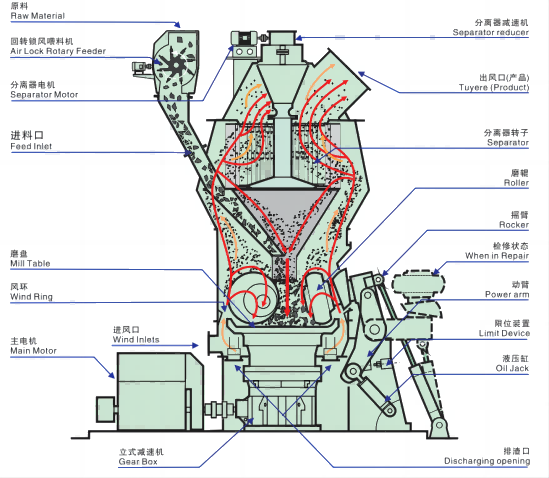

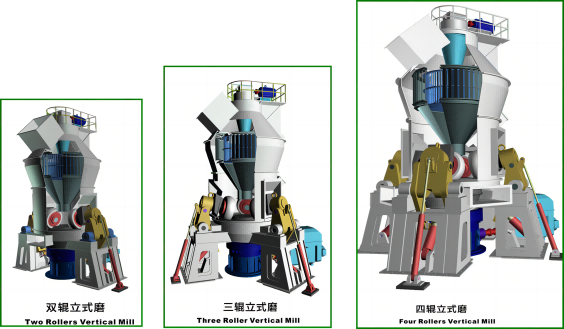

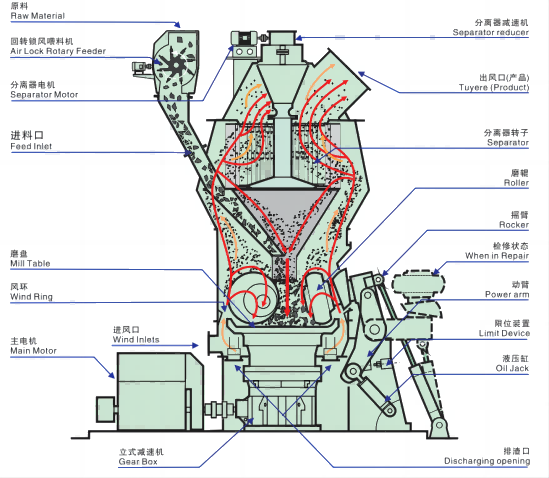

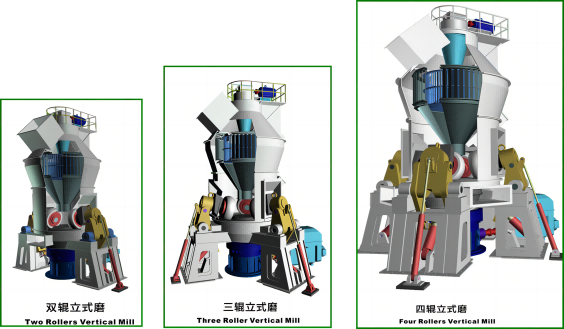

HVM vertical mill is a safe, environmentally friendly, energy-saving and efficient design based on extensive absorption of advanced technology of various vertical mills at home and abroad and learning from a large number of engineering experience. It is an advanced grinding equipment that integrates drying, grinding, powder selection and conveying functions. The main performance and economic and technical indicators of the equipment have reached the international advanced level.

Working principle: The motor drives the grinding disc to rotate through the reducer, and the material falls from the feeding port to the center of the grinding disc, and the hot air enters the grinding chamber from the air inlet. Under the action of centrifugal force, the material moves to the edge of the grinding disc, and is crushed by the grinding roller when passing through the circular groove on the grinding disc. The pulverized material is taken up by the high-speed airflow at the edge of the grinding disc at the edge of the grinding disc, and the large particles directly fall on the grinding disc. When re-grinding, the material in the airflow passes through the dynamic static separator. Under the action of the rotating rotor, the coarse powder falls on the grinding disc and milled again. The qualified fine powder gathered together with the airflow and collected in the collecting device. Then become product. The moisture-containing material is dried during contact with the hot gas to achieve the desired product moisture.

Main features of the product

1.High efficiency and energy saving:

(1) High grinding efficiency and low energy consumption, compared with ball mills, energy consumption is 40%-50% lower;

(2)The capacity of a single machine is large, and low valley electricity can be utilized;

(3)Vertical grinding technology and equipment is a new energy-saving and consumption-reducing technology, which is conducive to enhancing the competitiveness of enterprises in the field of powder industry in the region and the country;

2.Easy maintenance and low operating costs:

(1)The grinding roller can be turned out of the machine by hydraulic device. The replacement of the roller sleeve liner and the grinding machine has large maintenance space, and the maintenance operation is very convenient;

(2)The roller sleeve can be turned over to extend the service life of the wear-resistant material;

(3)There is no need to fabric on the grinding disc before starting the machine, and the mill can be started at no load, eliminating the trouble of starting the machine;

(4) Low wear, grinding roller and disc liner are made of special materials and have a long service life;

(5) High degree of automation: The automatic control technology adopts the German Siemens series PLC, equipped with automatic control system, which can realize remote control, easy operation, and the workshop can basically realize unmanned operation and save operating cost;

3.Low overall investment cost:

It integrates crushing, drying, grinding and conveying. It has simple process, few system equipment, compact structure and small floor space. It is only 50% of the ball mill. It can be arranged in the open air and has low construction cost, which directly reduces the investment cost of the enterprise.

4.Product quality is stable:

(1) The time of staying in the mill is short, and it is easy to detect the particle size distribution and composition of the product, and the product quality is stable;

(2)The product has a uniform particle shape, narrow particle size distribution, good fluidity and strong product adaptability.

5. High reliability

(1) Adopting the grinding roller limit device to avoid the violent vibration caused by the material breakage during the working time of the mill;

(2)The new type of grinding roller sealing device makes the sealing more reliable, and does not need to seal the fan, further reducing the oxygen content in the grinding, and the explosion suppression performance is more excellent.

6.Environmental protection:

(1)The whole system of HVM vertical mill has low vibration and low noise;

(2)The whole system is sealed, fully negative pressure running, no dust overflow, basically can achieve dust-free workshop.

Application field

With its scientific and reasonable design and unique structural advantages, HVM vertical mill is widely used in the grinding of various types of materials in all walks of life. The materials are from high humidity to dry materials, from abnormal to hard to grind. Easy to grind materials, product fineness from coarse to fine, the type of powder processed is rich, and the industries involved are numerous:

①Grinding material moisture: from 20-30% water (such as calcium carbide slag, lignite, chalk, etc.) materials to materials with less than 1% water (cement clinker, etc.), the material has strong adaptability;

②the grindability of the grinding material: from abnormally difficult to grind (such as quartz sand, steel slag, slag, pyrophyllite, iron ore, etc.) to easy to grind (such as gypsum, calcite, etc.);

③ fineness of grinding products: from 2 to 5mm (such as brick materials in the new wall material industry, sand shale in the construction industry, etc.) to a pass rate of 15um (such as papermaking, chemical industry grinding heavy calcium, etc.) Product fineness control is simple and easy.

HVM vertical mill application industry: building materials, electricity, steel, energy, thermal, chemical, coal chemical, non-ferrous metallurgy, lime kiln, mineral processing and other industries.

HVM vertical mill can handle materials: ferrite, slag, slag, cement, diamond, iron ore, chrome ore, manganese ore, gold, copper, aluminum, lead, zinc, antimony, polymetallic Mineral, nickel ore, bauxite, silicon carbide, titanium dioxide, talc, bentonite, calcite, kaolin, graphite, mica, wollastonite, feldspar, dolomite, pyrophyllite, quartz sand, fluorite, limestone, organic Silicon, lithium limestone, shale, volcanic ash, coal, etc.

HVM pulverized coal vertical mill specifications, technical parameters

| Model specification | HVM1100M | HVM1250M | HVM1300M | HVM1400M | HVM1500M |

| Capacity | 5~8 t/h | 8~10 t/h | 10~12 t/h | 12~15 t/h | 15~20 t/h |

| main motor power | 90 kW | 110/132 kW | 185/200 kW | 200/220 kW | 220/250 kW |

| Raw coal moisture | <15% | ||||

| Pulverized coal fineness | R0.08=2%~12% | ||||

| Pulverized coal moisture | ≤1%(Under the premise of meeting the drying requirements) | ||||

| Model specification | HVM1700M | HVM1900M | HVM2200M | HVM2400M | HVM2800M |

| Capacity | 20~25 t/h | 25~35 t/h | 35~45 t/h | 45~55 t/h | 70~90t/h |

| main motor power | 315/355 kW | 400/450 kW | 450/500 kW | 560/630 kW | 900/1120kW |

| Description | Note:1、The original coal Hastelloy grindability coefficient ≥ 55; | ||||

| 2、can be used for grinding anthracite, fineness of coal powder (R0.08) ≤ 3% (but the output will decrease accordingly) | |||||

HVM pulverized coal vertical mill specifications, technical parameters (Metallurgy, heat, energy industry)

|

Model specification |

HVM800M |

HVM1100M |

HVM1250M |

HVM1300M |

HVM1400M |

HVM1500M |

|||

|

Capacity |

3~5 t/h |

7~10 t/h |

9~12 t/h |

13~17 t/h |

14~19 t/h |

18~24 t/h |

|||

|

main motor power |

45/55 kW |

90/110 kW |

110/132 kW |

185/200 kW |

200/220 kW |

220/250 kW |

|||

|

Raw coal moisture |

<15% |

||||||||

|

Pulverized coal fineness |

R0.08=10%~15% (fineness of coal powder for blast furnace coal injection: 200 mesh 80% pass) |

||||||||

|

Pulverized coal moisture |

1%~6%(Under the premise of meeting the drying requirements) |

||||||||

|

Model specification |

HVM1700M |

HVM1900M |

HVM2200M |

HVM2400M |

HVM2800M |

||||

|

Capacity |

23~30 t/h |

29~36 t/h |

36~45 t/h |

45~55 t/h |

70~90t/h |

||||

|

main motor power |

280/315 kW |

355/400 kW |

450/500 kW |

560/630 kW |

900/1120kW |

||||

|

Description |

Note: The original coal Hastelloy grindability coefficient HGI:55~70 |

||||||||

HVM type high-fine vertical grinding specifications, technical parameter table (electric desulfurization)

|

Model specification |

HVM1250X |

HVM1300X |

HVM1500X |

HVM1700X |

HVM1900X |

HVM2400X |

HRM2600X |

HVM2800X |

|

Capacity |

6~9 t/h |

9~13 t/h |

15~20 t/h |

20~25 t/h |

26~32 t/h |

36~40 t/h |

45~55 t/h |

56~80 t/h |

|

Grinding material moisture |

≤5% |

|||||||

|

Limestone fineness |

325 mesh (44um) 90% passed |

|||||||

|

main motor power |

110/132 kW |

185/200 kW |

250/280 kW |

355/400 kW |

450/500 kW |

560/630 kW |

710/800kW |

1120/1250kW |

|

Description |

Note: Limestone Bon Grindability(Bond) Index: ≤13kWh/t |

|||||||

HVM type high-fineness vertical grinding specifications and technical parameter tables (non-metallic minerals, chemical industry, etc.)

|

Model specification |

HVM800X |

HVM1250X |

HVM1300X |

HVM1500X |

HVM1700X |

HVM1900X |

HVM2400X |

HVM2800X |

|

Capacity |

1~3 t/h |

2~7 t/h |

3~10 t/h |

4~15 t/h |

6~22 t/h |

7.5~25 t/h |

9~38 t/h |

11~45 t/h |

|

Grinding material moisture |

≤5% |

|||||||

|

Product fineness |

(10~40um)97% |

|||||||

|

Product moisture |

≤1% |

|||||||

|

main motor power |

55 kW |

132 kW |

180 kW |

250 kW |

355/400 kW |

450 kW |

560/630 kW |

710 kW |

|

Description |

Note: 1. The above technical indicators are based on materials with Mohs hardness of 3~4.

|

|||||||

HVM type coarse powder vertical mill specifications, technical parameters table (mineral processing and other industries)

|

Model specification |

HVM1100K |

HVM1250K |

HVM1300K |

HVM1500K |

HVM1700K |

HVM1900K |

HVM2200K |

HVM2400K |

HVM2800K |

|

Capacity |

5~7 t/h |

7~10 t/h |

11~13 t/h |

14~18 t/h |

20~25 t/h |

28~35 t/h |

35~45 t/h |

45~50 t/h |

65~80 t/h |

|

Grinding material moisture |

≤15% |

||||||||

|

Product fineness |

100 mesh (150um) 90% passed |

||||||||

|

Product moisture |

≤3% (Under the premise of meeting the drying requirements) |

||||||||

|

main motor power |

90/110 kW |

132/160 kW |

200/220kW |

250/280 kW |

355/400 kW |

500/560 kW |

630/710kW |

710/800 kW |

1120/1250kW |

|

Description |

Note: Minerals' Bon Grindability(Bond) Index: ≤22kWh/t |

||||||||

HVM vertical mill

HVM vertical mill is a safe, environmentally friendly, energy-saving and efficient design based on extensive absorption of advanced technology of various vertical mills at home and abroad and learning from a large number of engineering experience. It is an advanced grinding equipment that integrates drying, grinding, powder selection and conveying functions. The main performance and economic and technical indicators of the equipment have reached the international advanced level.

Working principle: The motor drives the grinding disc to rotate through the reducer, and the material falls from the feeding port to the center of the grinding disc, and the hot air enters the grinding chamber from the air inlet. Under the action of centrifugal force, the material moves to the edge of the grinding disc, and is crushed by the grinding roller when passing through the circular groove on the grinding disc. The pulverized material is taken up by the high-speed airflow at the edge of the grinding disc at the edge of the grinding disc, and the large particles directly fall on the grinding disc. When re-grinding, the material in the airflow passes through the dynamic static separator. Under the action of the rotating rotor, the coarse powder falls on the grinding disc and milled again. The qualified fine powder gathered together with the airflow and collected in the collecting device. Then become product. The moisture-containing material is dried during contact with the hot gas to achieve the desired product moisture.

Main features of the product

1.High efficiency and energy saving:

(1) High grinding efficiency and low energy consumption, compared with ball mills, energy consumption is 40%-50% lower;

(2)The capacity of a single machine is large, and low valley electricity can be utilized;

(3)Vertical grinding technology and equipment is a new energy-saving and consumption-reducing technology, which is conducive to enhancing the competitiveness of enterprises in the field of powder industry in the region and the country;

2.Easy maintenance and low operating costs:

(1)The grinding roller can be turned out of the machine by hydraulic device. The replacement of the roller sleeve liner and the grinding machine has large maintenance space, and the maintenance operation is very convenient;

(2)The roller sleeve can be turned over to extend the service life of the wear-resistant material;

(3)There is no need to fabric on the grinding disc before starting the machine, and the mill can be started at no load, eliminating the trouble of starting the machine;

(4) Low wear, grinding roller and disc liner are made of special materials and have a long service life;

(5) High degree of automation: The automatic control technology adopts the German Siemens series PLC, equipped with automatic control system, which can realize remote control, easy operation, and the workshop can basically realize unmanned operation and save operating cost;

3.Low overall investment cost:

It integrates crushing, drying, grinding and conveying. It has simple process, few system equipment, compact structure and small floor space. It is only 50% of the ball mill. It can be arranged in the open air and has low construction cost, which directly reduces the investment cost of the enterprise.

4.Product quality is stable:

(1) The time of staying in the mill is short, and it is easy to detect the particle size distribution and composition of the product, and the product quality is stable;

(2)The product has a uniform particle shape, narrow particle size distribution, good fluidity and strong product adaptability.

5. High reliability

(1) Adopting the grinding roller limit device to avoid the violent vibration caused by the material breakage during the working time of the mill;

(2)The new type of grinding roller sealing device makes the sealing more reliable, and does not need to seal the fan, further reducing the oxygen content in the grinding, and the explosion suppression performance is more excellent.

6.Environmental protection:

(1)The whole system of HVM vertical mill has low vibration and low noise;

(2)The whole system is sealed, fully negative pressure running, no dust overflow, basically can achieve dust-free workshop.

Application field

With its scientific and reasonable design and unique structural advantages, HVM vertical mill is widely used in the grinding of various types of materials in all walks of life. The materials are from high humidity to dry materials, from abnormal to hard to grind. Easy to grind materials, product fineness from coarse to fine, the type of powder processed is rich, and the industries involved are numerous:

①Grinding material moisture: from 20-30% water (such as calcium carbide slag, lignite, chalk, etc.) materials to materials with less than 1% water (cement clinker, etc.), the material has strong adaptability;

②the grindability of the grinding material: from abnormally difficult to grind (such as quartz sand, steel slag, slag, pyrophyllite, iron ore, etc.) to easy to grind (such as gypsum, calcite, etc.);

③ fineness of grinding products: from 2 to 5mm (such as brick materials in the new wall material industry, sand shale in the construction industry, etc.) to a pass rate of 15um (such as papermaking, chemical industry grinding heavy calcium, etc.) Product fineness control is simple and easy.

HVM vertical mill application industry: building materials, electricity, steel, energy, thermal, chemical, coal chemical, non-ferrous metallurgy, lime kiln, mineral processing and other industries.

HVM vertical mill can handle materials: ferrite, slag, slag, cement, diamond, iron ore, chrome ore, manganese ore, gold, copper, aluminum, lead, zinc, antimony, polymetallic Mineral, nickel ore, bauxite, silicon carbide, titanium dioxide, talc, bentonite, calcite, kaolin, graphite, mica, wollastonite, feldspar, dolomite, pyrophyllite, quartz sand, fluorite, limestone, organic Silicon, lithium limestone, shale, volcanic ash, coal, etc.

HVM pulverized coal vertical mill specifications, technical parameters

| Model specification | HVM1100M | HVM1250M | HVM1300M | HVM1400M | HVM1500M |

| Capacity | 5~8 t/h | 8~10 t/h | 10~12 t/h | 12~15 t/h | 15~20 t/h |

| main motor power | 90 kW | 110/132 kW | 185/200 kW | 200/220 kW | 220/250 kW |

| Raw coal moisture | <15% | ||||

| Pulverized coal fineness | R0.08=2%~12% | ||||

| Pulverized coal moisture | ≤1%(Under the premise of meeting the drying requirements) | ||||

| Model specification | HVM1700M | HVM1900M | HVM2200M | HVM2400M | HVM2800M |

| Capacity | 20~25 t/h | 25~35 t/h | 35~45 t/h | 45~55 t/h | 70~90t/h |

| main motor power | 315/355 kW | 400/450 kW | 450/500 kW | 560/630 kW | 900/1120kW |

| Description | Note:1、The original coal Hastelloy grindability coefficient ≥ 55; | ||||

| 2、can be used for grinding anthracite, fineness of coal powder (R0.08) ≤ 3% (but the output will decrease accordingly) | |||||

HVM pulverized coal vertical mill specifications, technical parameters (Metallurgy, heat, energy industry)

|

Model specification |

HVM800M |

HVM1100M |

HVM1250M |

HVM1300M |

HVM1400M |

HVM1500M |

|||

|

Capacity |

3~5 t/h |

7~10 t/h |

9~12 t/h |

13~17 t/h |

14~19 t/h |

18~24 t/h |

|||

|

main motor power |

45/55 kW |

90/110 kW |

110/132 kW |

185/200 kW |

200/220 kW |

220/250 kW |

|||

|

Raw coal moisture |

<15% |

||||||||

|

Pulverized coal fineness |

R0.08=10%~15% (fineness of coal powder for blast furnace coal injection: 200 mesh 80% pass) |

||||||||

|

Pulverized coal moisture |

1%~6%(Under the premise of meeting the drying requirements) |

||||||||

|

Model specification |

HVM1700M |

HVM1900M |

HVM2200M |

HVM2400M |

HVM2800M |

||||

|

Capacity |

23~30 t/h |

29~36 t/h |

36~45 t/h |

45~55 t/h |

70~90t/h |

||||

|

main motor power |

280/315 kW |

355/400 kW |

450/500 kW |

560/630 kW |

900/1120kW |

||||

|

Description |

Note: The original coal Hastelloy grindability coefficient HGI:55~70 |

||||||||

HVM type high-fine vertical grinding specifications, technical parameter table (electric desulfurization)

|

Model specification |

HVM1250X |

HVM1300X |

HVM1500X |

HVM1700X |

HVM1900X |

HVM2400X |

HRM2600X |

HVM2800X |

|

Capacity |

6~9 t/h |

9~13 t/h |

15~20 t/h |

20~25 t/h |

26~32 t/h |

36~40 t/h |

45~55 t/h |

56~80 t/h |

|

Grinding material moisture |

≤5% |

|||||||

|

Limestone fineness |

325 mesh (44um) 90% passed |

|||||||

|

main motor power |

110/132 kW |

185/200 kW |

250/280 kW |

355/400 kW |

450/500 kW |

560/630 kW |

710/800kW |

1120/1250kW |

|

Description |

Note: Limestone Bon Grindability(Bond) Index: ≤13kWh/t |

|||||||

HVM type high-fineness vertical grinding specifications and technical parameter tables (non-metallic minerals, chemical industry, etc.)

|

Model specification |

HVM800X |

HVM1250X |

HVM1300X |

HVM1500X |

HVM1700X |

HVM1900X |

HVM2400X |

HVM2800X |

|

Capacity |

1~3 t/h |

2~7 t/h |

3~10 t/h |

4~15 t/h |

6~22 t/h |

7.5~25 t/h |

9~38 t/h |

11~45 t/h |

|

Grinding material moisture |

≤5% |

|||||||

|

Product fineness |

(10~40um)97% |

|||||||

|

Product moisture |

≤1% |

|||||||

|

main motor power |

55 kW |

132 kW |

180 kW |

250 kW |

355/400 kW |

450 kW |

560/630 kW |

710 kW |

|

Description |

Note: 1. The above technical indicators are based on materials with Mohs hardness of 3~4.

|

|||||||

HVM type coarse powder vertical mill specifications, technical parameters table (mineral processing and other industries)

|

Model specification |

HVM1100K |

HVM1250K |

HVM1300K |

HVM1500K |

HVM1700K |

HVM1900K |

HVM2200K |

HVM2400K |

HVM2800K |

|

Capacity |

5~7 t/h |

7~10 t/h |

11~13 t/h |

14~18 t/h |

20~25 t/h |

28~35 t/h |

35~45 t/h |

45~50 t/h |

65~80 t/h |

|

Grinding material moisture |

≤15% |

||||||||

|

Product fineness |

100 mesh (150um) 90% passed |

||||||||

|

Product moisture |

≤3% (Under the premise of meeting the drying requirements) |

||||||||

|

main motor power |

90/110 kW |

132/160 kW |

200/220kW |

250/280 kW |

355/400 kW |

500/560 kW |

630/710kW |

710/800 kW |

1120/1250kW |

|

Description |

Note: Minerals' Bon Grindability(Bond) Index: ≤22kWh/t |

||||||||

- Prev:None

- Next: Rotary lock air feeder