Rotary lock air feeder

Release date:2019-07-19 Views:948

ALRF series rotary lock air feeder

★Description:

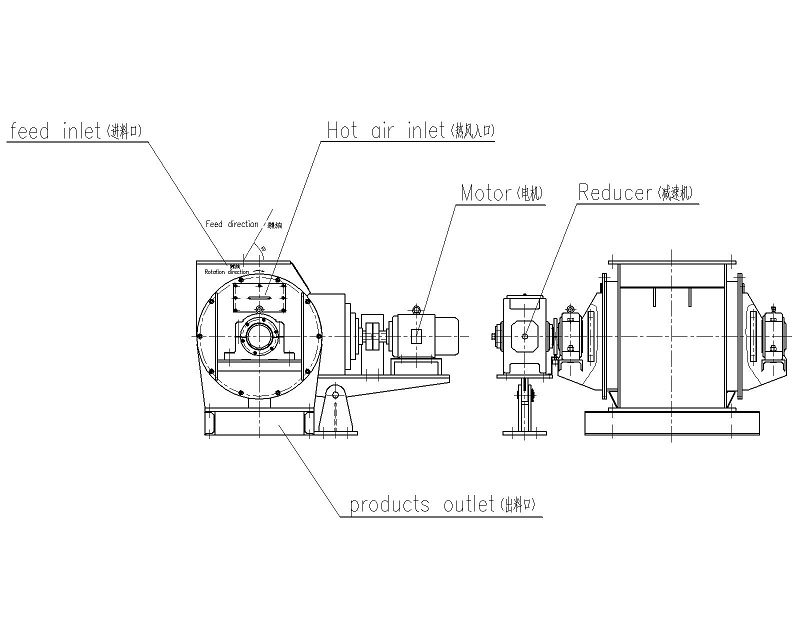

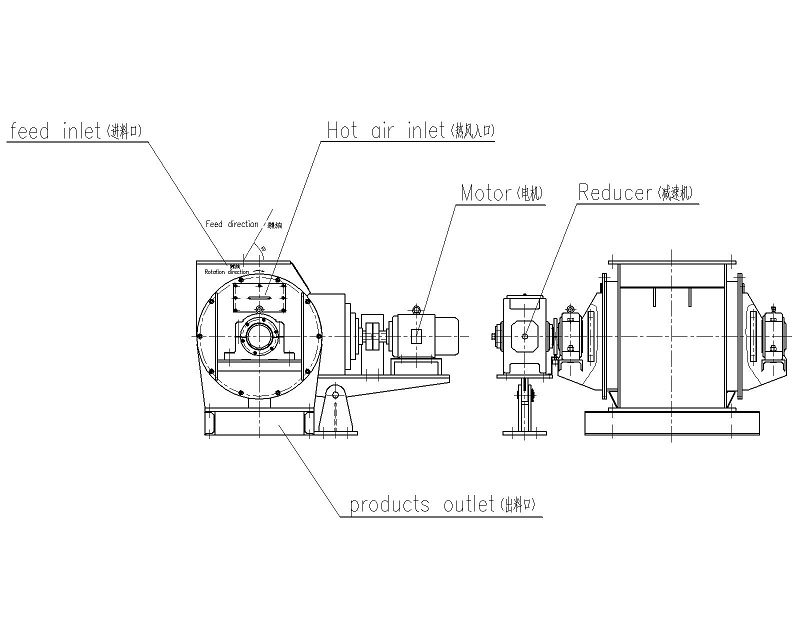

Working principle: The rotary lock air feeder is composed of a casing, a rotor, a driving part and the like. The inside of the feeder has a plurality of blades of the rotor, and the material of the upper silo is filled in the gap between the blades by its own weight, and the material is discharged at the lower port with the rotation of the rotor. Since the space between the rotor blades is uniform, the rotor speed is constant.

The rotor blade is made of special wear-resistant material to ensure good contact between the end of the blade and the inner wall of the shell, and the end of the blade can be easily adjusted after being worn, so that it still maintains good contact with the inner wall of the casing, and has a good gas lock. Features. The rotor can pass hot air and has certain drying ability, which can adapt to high moisture and viscous materials, prevent material from sticking and blocking materials.

This product can be used as a special wind lock feeder for vertical mills, or as a lock air feed device for wind sweep ball mills.

★ Main features of the product

The ALRF series rotary lock air feeder has the characteristics of small wear, good air lock effect and uniform feeding.

★ Application field

ALRF series rotary lock air feeder is suitable for powder materials and granular materials. It is widely used in cement, electric power, chemical, metallurgy, lime kiln, mineral processing and other industries.

ALRF series rotary lock air feeder

|

Specification model |

processing capacity |

Rotor speed |

Motor power& speed |

|

ALRF630×630 |

~35m3/h |

10.6r/min |

4kW/960r/min |

|

ALRF1000×1000 |

~120m3/h |

9.22r/min |

5.5kW/1440r/min |

|

ALRF1200×1200 |

~160m3/h |

8.26r/min |

7.5kW/1440r/min |

|

ALRF1600×1200 |

~360m3/h |

6.67r/min |

11kW/1460r/min |

|

ALRF1800×1400 |

~460m3/h |

6.67r/min |

15kW/1460r/min |

|

ALRF2200×1600 |

~700m3/h |

6.65r/min |

15kW/1460r/min |

ALRF series rotary lock air feeder

★Description:

Working principle: The rotary lock air feeder is composed of a casing, a rotor, a driving part and the like. The inside of the feeder has a plurality of blades of the rotor, and the material of the upper silo is filled in the gap between the blades by its own weight, and the material is discharged at the lower port with the rotation of the rotor. Since the space between the rotor blades is uniform, the rotor speed is constant.

The rotor blade is made of special wear-resistant material to ensure good contact between the end of the blade and the inner wall of the shell, and the end of the blade can be easily adjusted after being worn, so that it still maintains good contact with the inner wall of the casing, and has a good gas lock. Features. The rotor can pass hot air and has certain drying ability, which can adapt to high moisture and viscous materials, prevent material from sticking and blocking materials.

This product can be used as a special wind lock feeder for vertical mills, or as a lock air feed device for wind sweep ball mills.

★ Main features of the product

The ALRF series rotary lock air feeder has the characteristics of small wear, good air lock effect and uniform feeding.

★ Application field

ALRF series rotary lock air feeder is suitable for powder materials and granular materials. It is widely used in cement, electric power, chemical, metallurgy, lime kiln, mineral processing and other industries.

ALRF series rotary lock air feeder

|

Specification model |

processing capacity |

Rotor speed |

Motor power& speed |

|

ALRF630×630 |

~35m3/h |

10.6r/min |

4kW/960r/min |

|

ALRF1000×1000 |

~120m3/h |

9.22r/min |

5.5kW/1440r/min |

|

ALRF1200×1200 |

~160m3/h |

8.26r/min |

7.5kW/1440r/min |

|

ALRF1600×1200 |

~360m3/h |

6.67r/min |

11kW/1460r/min |

|

ALRF1800×1400 |

~460m3/h |

6.67r/min |

15kW/1460r/min |

|

ALRF2200×1600 |

~700m3/h |

6.65r/min |

15kW/1460r/min |